Galvalume Steel Coil

Home / Products / Steel Coil / Galvalume Steel Coil / Galvalume Steel Coil

Specification

Width: 700-1250mm

Thickness: 0.3-2.0mm

Inner Diameter: 508/610mm

Anti-Finger Print

Description

Galvalume steel coil is an aluminium-zinc alloy structure consisting of 55% aluminium, 43.4% zinc and 1.6% silicon solidified at 600°C. Its entire structure consists of aluminium - iron - silicon - zinc, forming a dense quadruple crystalline alloy.

During the current steel shortage, demand for any steel product, including coil, steel and sheet metal, has outstripped supply. As prices rise, coils are hard to come by. To serve our customers, galvalume steel coil manufacture brought in large volumes of steel coil at the height of the steel crisis. For all standard widths and sizes of Galvalume Steel Coil orders, we are able to offer you lower prices and immediate pickup or shipping.

With a deep understanding of the steel market cycle, our knowledge of the metals industry is second to none. Other experiential benefits include:

Expert engineers and skilled metallurgists design, develop and deliver reliable, durable products for the most challenging applications

For the galvanized sheet, a layer of zinc material is evenly distributed on the surface of the galvanized sheet, which plays a positive role in protecting the base metal, that is, zinc plays a role in replacing the corrosion protection and protecting the base metal. torn off.

The surface of the galvanized sheet is a coating composed of a small number of elements such as 55% aluminum and 43.5% zinc, which has a honeycomb structure under the microscope. Aluminium honeycomb wraps zinc. In this case, although the aluminum-zinc coating also plays a protective role for the positive electrode, due to the decrease in zinc content, the aluminum-clad zinc is not easy to be electrolyzed, and this protective effect drops sharply.

Therefore, once a galvanized sheet is cut, the cut edges often lose their protection and rust quickly. So we should cut as little as possible, and once the cut occurs, use anti-rust paint or zinc-rich paint to protect the edge and prolong its life.

Unique protective properties and affordability make galvanized steel coil and sheet ideal for a wide range of applications including but not limited to:

● Residential and Commercial Exterior Building Products

● Roof

● Siding

● Cupboard

● Air conditioning and heating equipment

● Electrical box

● Agricultural Equipment and Machinery

● Furnace Accessories

● Guide

● Home appliances

performance well above 300 °C

The aluminum layer protects the inside of the steel

Galvalume steel provides perfect adhesion to make your finish more attractive

If you want to buy galvalume steel coil online, please contact us and we will provide you with the most suitable price.

Sure, yes. GL board is light in weight but strong in strength and is a new type of roofing material. In addition, GL roof panels are preferred in hot climates due to their high thermal reflectivity. In addition, it has a gorgeous and smooth appearance, so it is widely used in commercial, civil and public buildings.

Package

plastic film + water proof paper + steel plate+ packing steel strip

Advantages

Machinability

Aluzinc steel coil can satisfy the processing requirements of rolling, coiling and other processes alike.

Thermal

Common HDG steel plate normally works under 230℃, and has its color changed at 250℃, however, galvalume steel coil can sustain the environment at 315℃ for long time resistance.

Resistance to Corrosion

Aluzinc steel coil has better performance in corrosion resistance than GI sheet of the same thickness and its service life is 2-6 times longer than general GI sheet.

Galvalume steel coil refers to a 55% galvanized steel sheet product that is ideal for roofing and siding applications, as well as automotive, home appliances, furniture, and more. Galvalume steel coil is popular for its versatility, durability and aesthetics.

Advantage:

Strong corrosion resistance, 3 times that of galvanized steel coil.

The density of 55% aluminum is less than that of zinc. With the same weight and the same coating thickness, the area of the galvalume steel coil is more than 3% larger than that of the galvanized steel sheet.

Major Function

Aluzinc steel coil are widely used in the construction industry, industrial instrumentation, household appliances, automotive parts, etc.

| Doors | Electric control cabinet | Outer Clad Sheets | Muffler |

| Roofs and outside walls of civilian and fencing and window blinds industrial buildings, garage doors. | Industrial refrigeration equipment automatic vending machine. | Outer clad sheets for washing machine, refrigerator, TV, and ventilation system, explosion-proof strip,air conditioner solar water heater and appliance parts. | Heat shields of exhaust pipe and, auto parts & accessories under the frame, catalytic converter, signboard in highway. |

Technology

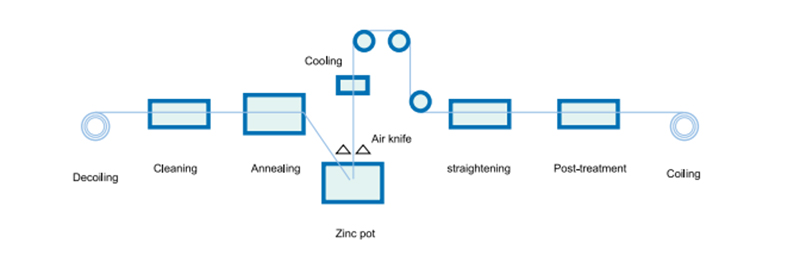

Detailed steps of Galvalume steel coil processing

step 1:

Pre-treatment: After the cold-rolled steel coil arrives at the galvanizing workshop, it goes through the uncoiler, the degreasing section and the reduction furnace to clean the steel coil and restore its composition to the extent that it can be galvanized.

Step 2:

Middle section: The most critical technology is this step. After passing through the zinc pot, the surface of the steel plate is coated with a zinc layer. After coming out of the zinc pot, it is cooled and shaped by a cooling tower.

Step 3:

Post-treatment: The steel plate finally enters the post-treatment stage after going through various processes. After finishing, straightening and passivation, and finally coiling.