Hot Rolled Steel Coil

Home / Products / Steel Coil / Hot Rolled Steel Coil / Hot Rolled Steel Coil and Plate

Specifications:

Thickness: 1.2-25.4mm

Width: 600-2150mm

Package: The inner packing is plastic film and waterproof paper, outer packing is galvanized steel or coated steel, side shield, then wrapped with steel belt.

Materials: Carbon structural steel Q195, Q215, Q235, Q275 2.5-18 800-1100 C GB/T 700-2006.

Description

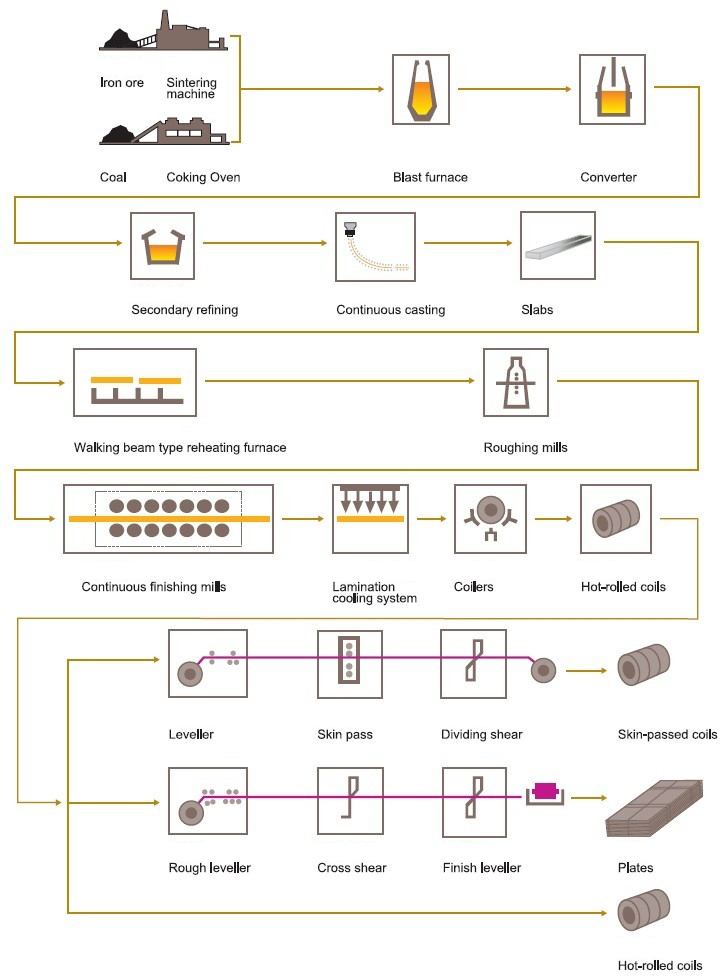

Hot rolled steel coil(HRC Steel) and plate are made from slabs, heated and rolled by roughing and finishing units. Also named hot rolled carbon steel coil and plate.

The first step in the hot rolling process is to heat the steel, elemental or mineral mixture to a high temperature above its recrystallization temperature. Once it is heated above this point, the steel becomes ductile. It is then sent to a rolling machine where it can be easily shaped. With this hot-rolled carbon steel process, it can produce large quantities of steel in a single batch as minimal additional machining is required.

After carbon steel is processed, it is normalized by cooling to room temperature. The process of heating and slow cooling of steel changes the metal's microstructure, increasing its ductility and strength. When forming steel, increasing ductility is an important factor in obtaining the desired shape. The exact combination of elements added to the iron content determines the grade of steel and its unique strength, formability and hardness properties. Carbon and manganese are the two main additional elements that affect the outcome of a particular grade of material, but other elements can also play a key role.

In addition, hot rolled steel shrinks slightly during the cooling phase, resulting in a slight change in accuracy; thickness and width of the coil. The finished product does not always meet the specific goals originally intended. Therefore, for flat steel products, there are standard tolerances and ranges defined by the industry. The production of hot rolled steel is both an art and a science that really requires a delicate balance. Often, additional and off-the-shelf treatments are required for areas that require tight tolerances.

Hot-rolled mild steel has been rolled at high temperatures from slabs of cast steel over two inches thick to coils as thin as 1/16-inch thick.

Because the steel is hot rolled, the degree of reduction from the slab to the coil is high, so the surface of the coil is noticeably rough and slightly oxidized. Recommended for hot rolled strip of precise thickness and high formability.

Hot-rolled mild steel is less expensive than cold-rolled steel because it is not treated after hot rolling except that it requires pickling to remove surface scale. Hot Rolled Steel Coil Factory provides hot rolled mild steel plate and coil for your application.

If you want to know more information about hot rolled carbon steel coil , please contact us. We will provide professional answers.

1. Due to the good welding performance of hot-rolled carbon steel coil flat products, the welding requirements are not too high in the case of not thick plates, and the AC spot welding machine can meet the welding requirements.

2. If the equipment cost allows, try to use the medium frequency inverter spot welding machine to spot weld the mil steel plate. The welding effect is better, the nugget and the welded joint will be more perfect.

3. There are cold-rolled steel plates and hot-rolled steel plates. Cold-rolled steel plates do not need special cleaning before welding, while hot-rolled steel plates must remove impurities such as oxidation, rust, and oil stains on the surface.

4. If the capacity of the spot welding machine used allows, it is recommended to use hard specification welding to reduce the influence of thermal diffusion on the product and also reduce the deformation of the product.

Hot rolled sheets and coils are basic carbon steel products that are commonly used in applications:

● Agricultural equipment

● Auto parts

● Car frame

● Put up

● Pipe and Tubular

● Rail

● Strapping

● Stamping

● Transport infrastructure

Advantages

High Strength

HRC Steel has high comprehensive mechanical properties. It can be used in the construction of large machinery and engineering, and also as the raw material for large welded structural parts.

Good Toughness

HRC Steel has good toughness. After heat treatment, it can also be used to make many mechanical parts.

Easy Processing and Forming

It has good ductility, strong plasticity, easy processing, and can be made into a variety of shapes.

Hot rolled carbon steel coil have excellent properties such as high strength, good toughness, easy processing and forming, good weldability, etc.

Major Function

Hot rolled steel coil widely used in ships, automobiles, bridges, construction, machinery, pressure vessels and other manufacturing industries. Also it is produced into hot rolled steel strip for lashing or packaging.

| HRC Steel plate for building steel structure | HRC Steel Plate for welded pipe | HRC Steel plates for shipbuilding | HRC Steel general structural plates for agricultural vehicles and automobiles | HRC Steel plate can be produced into Hardware, accessories equipment with. |

| used in high-rise buildings, airports, gymnasiums, exhibition halls and other buildings. | used for welding large diameter spiral and straight seam steel pipes of 800mm or more. Steel pipes are used in the laying of fluid transportation pipelines for oil, natural gas, urban plumbing, gas networks, etc. | applied to above-deck construction, with low quality requirements. | applied to the bottom plate of vehicle cargo boxes in agricultural vehicles, concentrating on thickness 1.5/1.8/2mm, and applied to the manufacture of laden vehicles in automobiles. |

Technology