Galvanized Steel Coil

Home / Products / Steel Coil / Galvanized Steel Coil / Galvanized Steel Coil

Specification

Thickness: 0.12-2.5mm

Width: 100-1500mm

Zinc Coated: 30-275g/m2

Inner Diameter: 508/610mm

Grade: DX51D SGCC DX52D ASTMA653 JISG302

Surface Structure: no spangle, minimized spangle, Maximum spangle, regular spangle

Surface Treatment: oiled, passivated or chrome-free passivated, passivated + oiled

Description

Introduction:

Galvanized steel coil, thin steel sheets that are dipped into a molten zinc bath so that a layer of zinc adheres to their surface. Currently it is mainly produced by the continuous galvanizing process, whereby rolls of steel sheet are continuously dipped into a bath of molten zinc to make a galvanized steel sheet; alloyed galvanized steel sheet. This steel is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to around 500°C to produce an alloy of zinc and iron.

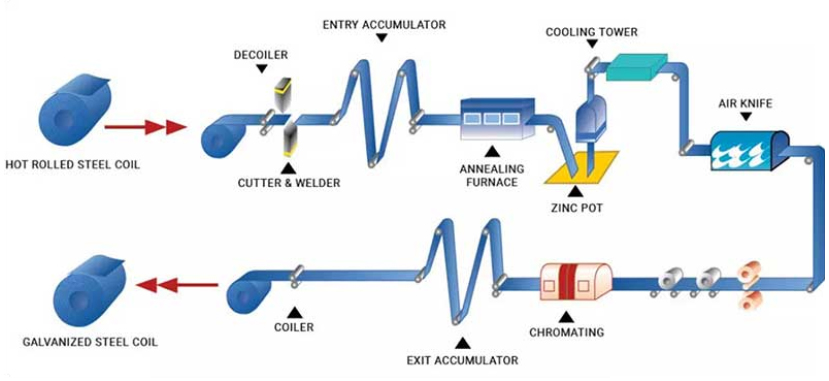

Galvanizing Process:

1.Surface Preparation:

The steel coil is cleaned to remove any contaminants, rust, or mill scale from the surface, ensuring good adhesion of the zinc coating.

2.Galvanizing Bath:

The cleaned steel coil is then immersed in a bath of molten zinc at temperatures typically ranging from 430°C to 460°C (800°F to 860°F). The steel is coated with a layer of zinc through a metallurgical reaction known as galvanization.

3.Formation of Zinc Coating:

When the steel coil is immersed in the molten zinc, a series of alloy layers are formed on the surface of the steel, creating a protective zinc coating. This coating provides corrosion resistance and enhances the durability of the steel.

4.Thickness and Size:

Galvanized steel coil is available in various thicknesses and widths to suit different applications and manufacturing requirements. The thickness of the zinc coating, often referred to as the coating weight, can be specified according to industry standards or customer preferences.

Properties:

1.Corrosion Resistance:

The zinc coating acts as a barrier between the steel substrate and the surrounding environment, protecting the steel from corrosion, rust, and oxidation.

2.Durability:

The zinc coating provides added durability and longevity to the steel, making it suitable for outdoor and high-moisture environments.

3.Paintability:

Galvanized steel coil can be easily painted or coated with additional protective coatings to enhance its appearance and further improve its corrosion resistance.

4.Formability:

Galvanized steel coil retains its formability and ductility even after the galvanizing process, allowing it to be easily formed, shaped, and fabricated into various products and components.

5.Applications:

Galvanized steel coil is used in a wide range of applications across industries, including construction, automotive, agricultural, HVAC, appliances, and manufacturing. It is commonly used to fabricate roofing, siding, gutters, fences, HVAC ductwork, automotive parts, electrical enclosures, and structural components.

In summary, galvanized steel coil is a versatile and durable steel product that has been coated with a protective layer of zinc through a hot-dip galvanizing process. Its corrosion resistance, durability, paintability, formability, and wide range of applications make it a popular choice in various industries.

Transportation: Auto Panel; Carriage Panel;

Package

plastic film + water proof paper + steel plate+ packing steel strip

We are professional Galvanized Steel Coil for Sale manufacturers, please contact us and we will give you a satisfactory solution.

|  |

Advantages

Anticorrosive

13 years in heavy industrial areas, 50 years in the ocean, 104 years in the suburbs and 30 years in cities.

Cheap

The cost of hot-dip galvanizing is lower than that of other coatings also with high quality.

Reliable

The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

Strong Toughness

The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

Comprehensive Protection

Every part of the plated piece can be galvanized, and is fully protected even in depressions, sharp corners, and hidden places.

Save Time and Energy

Galvanizing process is faster than other coating methods.

Gi coil with good paint adhesion and weldability

Major Function

Galvanized steel coil is widely used in ship, automobile, Bridges, buildings, machinery, pressure vessels and other manufacturing industries.

| Building & Construction | Door | Interior Decorations | Household Appliances |

| Roofing; Terrace; Window Frame; | Rolling-up Door; Shutter; Mobile House; | Wall; Door Frame; Steel Structure; Screen; Ceiling; Elevator. | Fridge; Washing Machine; Microwave Oven; Air-Conditioner; Duplicating Machine, etc; |

Technology