I Beam Steel

Home / Products / Steel Section / I Beam Steel / I Beam Steel

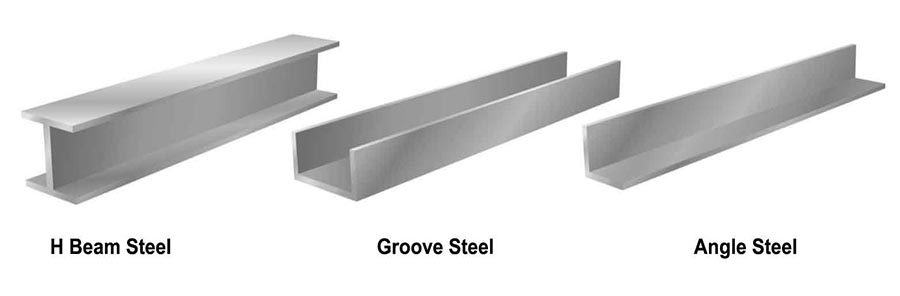

I-shaped steel is an efficient and economical cutting profile (others include cold-formed thin-walled steel, profiled steel plates, etc.). They can make the steel more efficient and improve its cutting capacity. Different from the ordinary H-shaped steel, the flange of the I-shaped steel is widened, and the inner and outer surfaces are usually parallel, which makes it easy to connect with other components with high-strength bolts. Its size constitutes a reasonable series with complete models, which facilitates engineering design.

Material: Q235, Q345, A36, Gr50, S235JR, S335JR

Description

I beam steel features a long, horizontal top flange and a vertical web, connected by a shorter bottom flange. This unique "I" shape provides excellent load-bearing capacity and structural stability, making it widely used in construction and structural engineering applications.

I beam steel is typically made from carbon steel or low-alloy steel, although other materials such as stainless steel or aluminum may also be used for specialized applications. The choice of material depends on factors such as strength requirements, corrosion resistance, and cost considerations.

I beam steel is produced through a process called hot rolling, where heated steel billets or slabs are passed through rolling mills to form the desired shape. The steel is shaped and stretched under high pressure, resulting in a uniform and precise I-shaped profile.

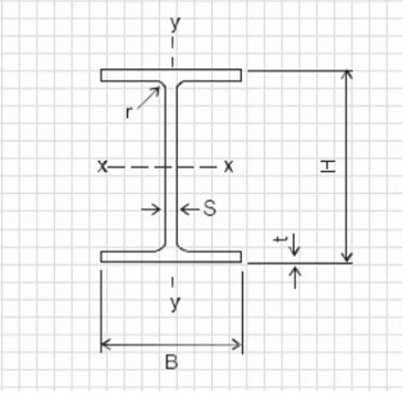

I beam steel is available in a wide range of sizes and dimensions to suit various construction and engineering requirements. Standard sizes are specified by their depth (height of the web) and weight per unit length, such as "W10x22" or "HEA 200". These dimensions indicate the height, width, and weight of the beam.

I beams are commonly used as structural support elements in buildings, bridges, and other infrastructure projects. They provide strength, stability, and load-bearing capacity, allowing for the construction of large and durable structures.

I beams are used in bridge construction to support roadway decks, spans, and structural components. They can withstand heavy loads and provide stability over long distances, making them ideal for bridge construction.

I beams are used in industrial and commercial buildings to support roof and floor systems, mezzanines, and overhead cranes. They provide structural integrity and allow for flexible floor plans and layouts.

I beams are used in marine and offshore structures such as oil platforms, shipyards, and dock facilities. They can withstand harsh environmental conditions, including saltwater corrosion and high winds.

I beams are used in the construction of machinery frames, conveyor systems, and equipment supports in manufacturing and industrial settings. They provide rigidity, stability, and support for heavy machinery and equipment.

In summary, I beam steel is a versatile and widely used structural steel profile with a distinctive "I" shape. Its strength, stability, and load-bearing capacity make it suitable for a variety of construction, engineering, and industrial applications.

We are professional I Beam Steel Supplier, please contact us and we will give you a satisfactory solution.

I Beam Steel

Parameter:

Nominal Size(mm) | H*B(mm) | T1(mm) | T2(mm) | JIS Wight (kg/m) | GB Wight (kg/m) | Available Length |

100x100 | 100x100 | 6 | 8 | 16.9 | 17.2 | 6-12 |

150x100 | 148x 100 | 6 | 9 | 20.7 | 21.4 | 6-12 |

150x150 | 1 50x150 | 7 | 10 | 31.1 | 31.9 | 6-12 |

200x100 | 198x99 | 4.5 | 7 | 17.8 | 18.5 | 6-12 |

200x100 | 5.5 | 8 | 20.9 | 21.7 | 6-12 | |

200x200 | 200x200 | 8 | 12 | 49.9 | 50.5 | 6-12 |

200x204 | 12 | 12 | 56.2 | 56.7 | 6-12 | |

300x300 | 300x300 | 10 | 15 | 93 | 94.5 | 6-12 |

294x302 | 12 | 12 | 83.4 | 85 | 6-12 | |

300x 305 | 15 | 15 | 105 | 106 | 6-12 | |

400x 300 | 390*300 | 10 | 16 | 105 | 107 | 6-12 |

500x300 | 482x300 | 11 | 15 | 11.1 | 115 | 6-12 |

488x300 | 11 | 18 | 125 | 129 | 6-12 | |

600*300 | 582*300 | 12 | 17 | 133 | 137 | 6-12 |

588x300 | 12 | 20 | 147 | 151 | 6-12 | |

594x302 | 14 | 23 | 170 | 175 | 6-12 | |

700x300 | 692x300 | 13 | 20 | 163 | 166 | 6-12 |

700x300 | 13 | 24 | 182 | 185 | 6-12 | |

800x300 | 800x300 | 14 | 26 | 207 | 210 | 6-12 |

808x302 | 16 | 30 | 241 | 6-12 | ||

900x300 | 890x299 | 15 | 23 | 210 | 213 | 6-12 |

900x300 | 16 | 28 | 240 | 243 | 6-12 |

Advantages

Compared with welding I-shaped steel, it can significantly save labor and materials, reduce the consumption of raw materials, energy and labor, low residual stress, and good appearance and surface quality.

Major Function

I-shaped steel is widely used, mainly for various civil and industrial building structures; Various large-span industrial factories and modern high-rise buildings, especially in areas with frequent seismic activity and under high-temperature working conditions; Large bridges with high load-bearing capacity, good cross-sectional stability, and large spans are required; Heavy equipment; Expressway; Ship skeleton; Mine support; Foundation treatment and embankment engineering; Various machine components.

Hot rolled I-beam steel has excellent mechanical properties and excellent service performance by distributing the aspect ratio of section size reasonably according to different applications.